Our Process

Our spirits are made from NC grown grain from a family farm in Union County. Brothers and cousins share the land and it is not uncommon for one of their young boys to accompany their grain delivery to our distillery.

It’s important to us to know our farmers and to commit to their harvest, year after year.

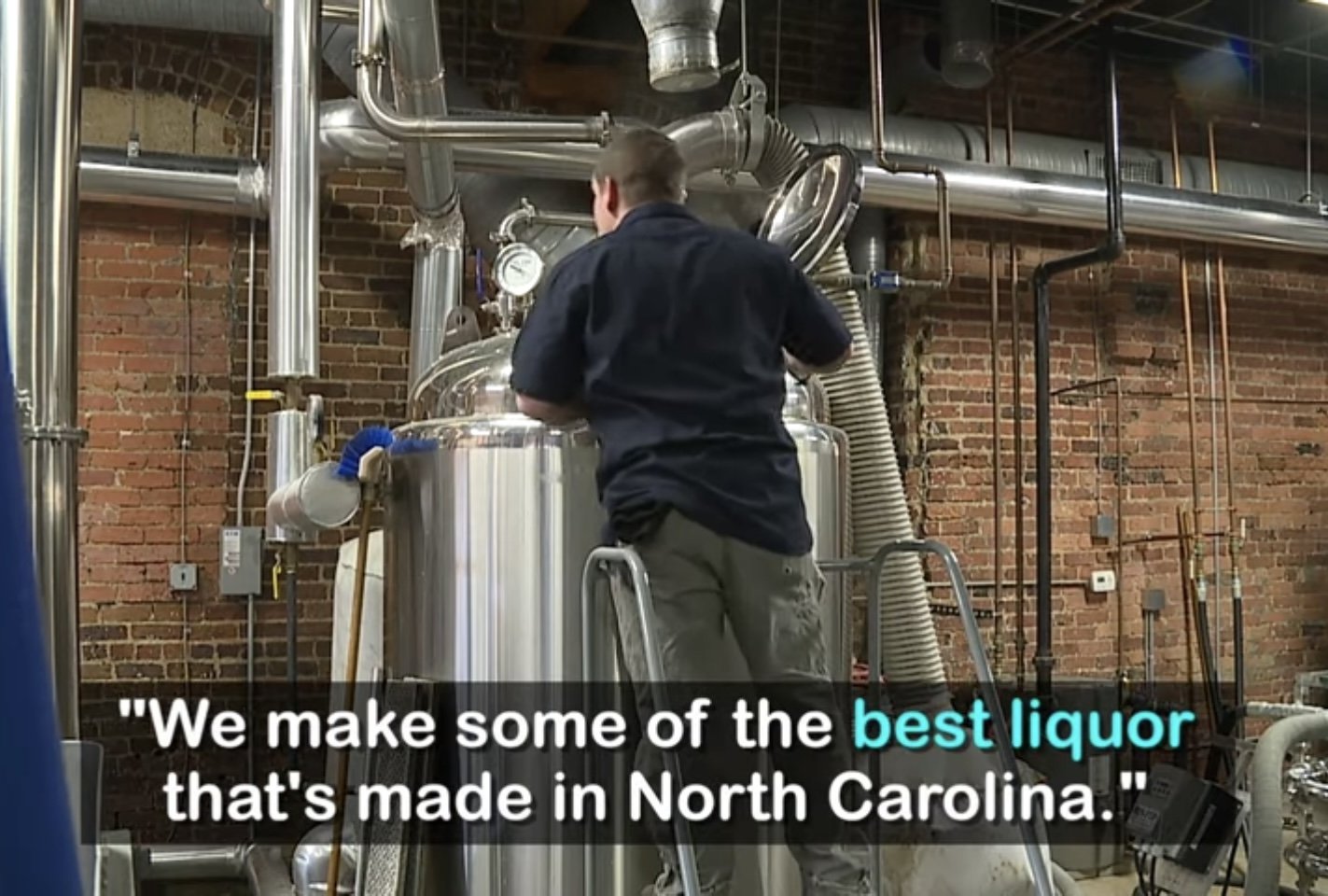

Assistant Distiller Dave grinds the fresh grain every morning transferring it to the mash tun where it’s cooked to perfection before moving it to the fermenting tanks.

Fermentation of the mash takes about 7 days. Grains are mostly starch, protein and fiber. For fermentation to work, starches must be broken down into simple fermentable sugars to enable the yeast to consume them in order to produce alcohol that we simply refer to as distillers beer. Mash temperatures must be maintained precisely in order to get the maximum levels of fermentable sugars out of the grain without damaging the critical enzymes so as the fermentation process is producing heat, we are cooling our tanks with glycol to insure we produce the highest yield of alcohol.

Once a liquid fermentation is finished, the liquid is then transferred to the still and heated. As the liquid is increased slowly from room temperature to approximately 190 degrees (F), the liquid vaporizes and rises through the column. Once it reaches the condenser it comes in contact with a cold surface and condenses back into a liquid state. It then exits the still in the form of a number of different chemicals. However, all the distiller wants is the ethanol. Through the process known as “cutting” our seasoned head distiller, Andrew is able to segregate the different chemicals leaving the ethanol in a pure state.

The finishing process is the final process before bottling. This process has a few different steps, and depending on the alcohol type desired will depend on which of these steps you would use.

Filtering – Filtering alcohol primarily does 2 things. It removes off flavors and it smooths out the overall taste and flavor.

Flavoring – If you macerate botanicals in the spirit, or use some type of spice to influence the taste, flavor profiles are almost endless.

Oaking/Aging – Whiskey doesn’t get its color from the grains used in the fermentation process. Instead it gets its color from the oak in which it is stored. Although it gets much of its flavor from the grains, another layer of flavor is also added through the oak, or other hardwood, used in the aging process. Same goes with bourbon, which requires a brand new white oak barrel.

The finishing process is a step that is kept in mind from the beginning of fermentation. Often you will choose certain grains based on the type of finishing you plan.